In the realm of technological advancements, 3D printing has emerged as a revolutionary tool, bridging the gap between the digital and physical worlds. This technology, coupled with digital twin simulations, is transforming industries, from manufacturing and healthcare to aerospace and construction.

The Power of 3D Printing and Digital Twins

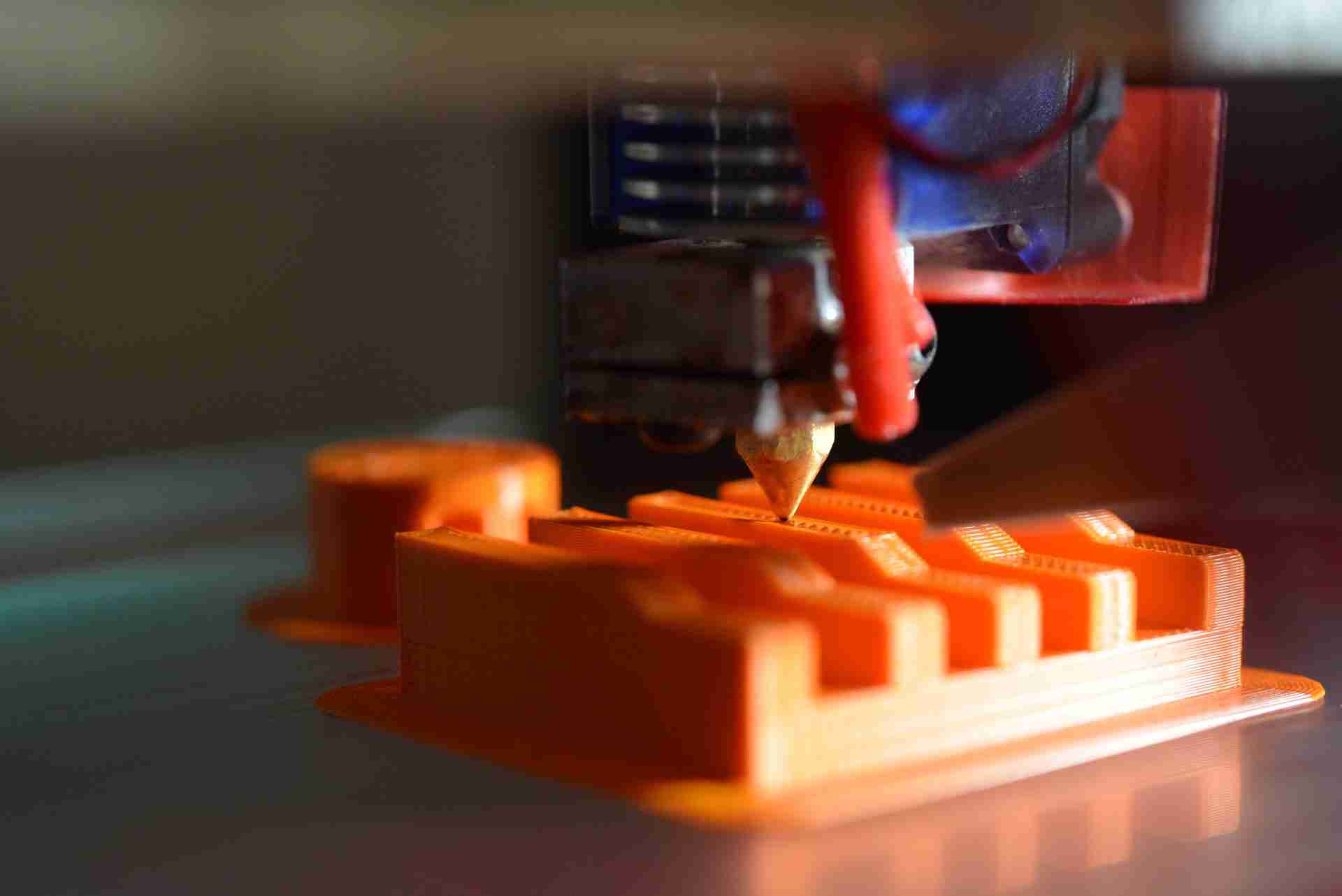

3D printing, or additive manufacturing, is a process that creates physical objects from digital models. It allows for the production of complex and customized designs with high precision, which was previously impossible or extremely costly with traditional manufacturing methods.

On the other hand, digital twins are virtual replicas of physical entities. They enable real-time monitoring, testing, and optimization of objects, processes, or systems in a safe digital environment. When combined, these two technologies provide a powerful tool for innovation.

The Evolution of 3D Printing

3D printing has evolved significantly over the years. It started with simple plastic models and has now expanded to include a wide range of materials, including metals, ceramics, and even biological materials. This has opened up new possibilities in various fields.

In healthcare, 3D printing is used to create customized prosthetics, implants, and even organ models for surgical planning. In aerospace, companies are using 3D printing to produce complex parts that are lighter and more efficient. In the construction industry, 3D printing is being used to create entire buildings, reducing construction time and waste.

4D Printing and Beyond

The future of 3D printing lies in the development of 4D printing, where the fourth dimension is time. 4D printed objects can change shape or properties over time in response to stimuli such as heat, light, or moisture. This technology is still in its early stages, but it holds great potential for creating smart materials and structures that can adapt to their environment.

The Role of 3D Printing in the COVID-19 Pandemic

The COVID-19 pandemic has highlighted the versatility and rapid response capability of 3D printing. From producing personal protective equipment (PPE) for healthcare workers to creating nasopharyngeal swabs for testing, 3D printing has played a crucial role in addressing supply chain disruptions and meeting urgent needs.

Conclusion:

3D printing is not merely a tool for creating objects; it’s a transformative technology that serves as a bridge between the digital and physical worlds. This bridge is not a one-way path but a dynamic, two-way interaction that allows for continuous feedback and improvement.

As 3D printing technology continues to evolve, it is integrating with other cutting-edge technologies like digital twins and 4D printing. Digital twins allow for real-time monitoring and optimization in a safe digital environment, while 4D printing introduces the concept of time, creating objects that can change and adapt over time.

These advancements are not just enhancing our ability to design and produce objects, but they are also transforming entire industries. From healthcare and aerospace to construction and manufacturing, 3D printing is revolutionizing the way we approach design and production. It allows for greater customization, reduces waste, accelerates production times, and opens up new possibilities for innovation.

Moreover, the role of 3D printing in response to the COVID-19 pandemic has demonstrated its potential in crisis management. It has shown that 3D printing can rapidly respond to urgent needs, address supply chain disruptions, and provide innovative solutions to unprecedented challenges.

As we look to the future, the potential applications of 3D printing are vast and largely unexplored. It’s an exciting time as we continue to push the boundaries of what’s possible with 3D printing. As this technology becomes more accessible and integrated into various sectors, it will continue to blur the lines between the digital and physical worlds, opening up a world of possibilities that we are just beginning to imagine.

In conclusion, 3D printing is not just shaping our physical world; it’s reshaping the way we think about design, innovation, and production. It’s a testament to human ingenuity and a glimpse into a future where the digital and physical worlds are seamlessly integrated.

Read also our article “The High Cost of AI Adoption: Is Your Company Ready?“.

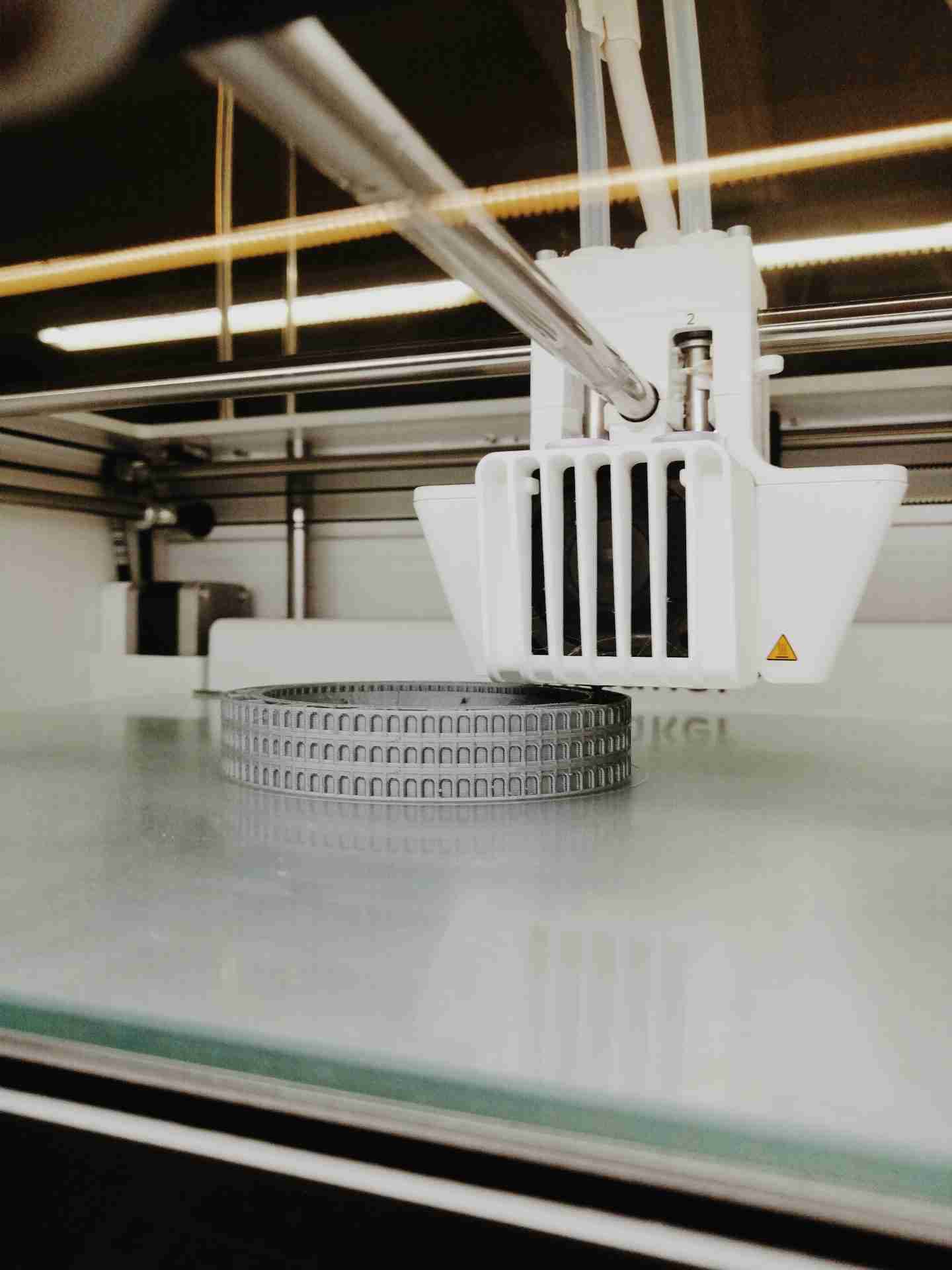

The price of 3D printing has decreased over the years. Here is an example of an affordable 3D printer “ANYCUBIC Vyper 3D Printer“.